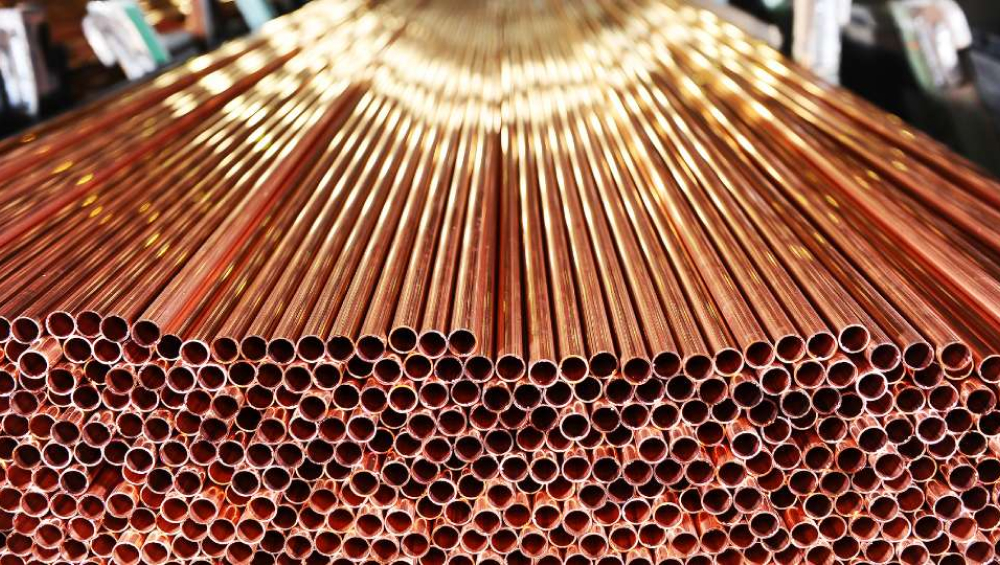

The global copper smelting sector is currently facing unprecedented challenges as treatment charges (TCs) take a nosedive. The 2025 benchmark, established by Chile’s Antofagasta and China’s Jiangxi Copper, has plummeted to just $21.50 per ton and 2.125 cents per pound. This is a significant drop from this year’s $80 per ton and marks the lowest TCs seen in at least two decades.

Unlike previous downturns which were caused by mine supply shortages, this drastic decline is driven by overcapacity in global smelting operations. This is particularly evident in China, where smelting capacity is rapidly expanding at an unsustainable rate. As a result, the industry is grappling with fierce competition and dwindling margins in the copper market.

China Copper Smelting Overcapacity & Market Impact

China’s copper smelting capacity is projected to experience a significant surge, increasing from 14.26 million tons in 2024 to nearly 17 million tons by 2027, as reported by Ge Honglin of the China Nonferrous Metals Industry Association. This rapid and substantial expansion is not just a matter of increasing numbers; it represents a strategic push by China to dominate the global copper smelting market.

However, this aggressive growth is creating a critical overcapacity issue that is further exacerbating the ongoing slump in treatment charges. The industry is finding itself in a precarious position where the supply of smelting capacity far exceeds the demand, leading to a downward spiral in treatment fees.

Despite reaching agreements aimed at curbing output to stabilize the market, Chinese producers have encountered significant challenges in effectively implementing these production cuts. The national output has continued to grow, increasing by 5% year-on-year from January to November, which starkly highlights the minimal impact of these efforts to control production. This persistent overcapacity is not just a domestic issue but is contributing to a global imbalance in the copper smelting industry. The excess capacity is flooding the market, driving treatment charges to historic lows, and creating a highly competitive environment where only the most efficient and adaptable copper smelters can hope to survive. The situation calls for urgent strategic interventions to prevent further destabilization of the copper market.

Global Competition for Copper Concentrates

The global competition for raw materials is intensifying as new smelting facilities come online in various countries, including Indonesia, the Democratic Republic of Congo, and India. These nations are rapidly developing their smelting capabilities, driven by a desire to capitalize on the lucrative copper market and reduce their reliance on imported refined copper.

As these new entrants establish themselves, they will absorb a larger share of the mined concentrates, thereby limiting the availability for other smelters around the world. This shift is expected to create a more competitive landscape, where established copper smelters must vie for a dwindling supply of raw materials, potentially driving up costs and squeezing profit margins.

While the International Copper Study Group (ICSG) forecasts a 3.5% growth in mine supply for 2025, this increase is unlikely to meet the soaring demand from global smelters. The anticipated growth in mine output may not be sufficient to satisfy the burgeoning needs of the expanding smelting industry, which is hungry for raw materials to fuel its operations. The first nine months of 2024 saw a 402,000-ton refined copper surplus, indicating a significant bottleneck in smelter operations rather than mine supply. This surplus suggests that while there is enough copper being mined, the capacity to process and refine it into usable forms is lagging, creating a disconnect between supply and demand. This bottleneck highlights the challenges faced by smelters in efficiently processing the available raw materials, further exacerbating the competitive pressures in the industry.

Scrap Copper Supply & Trade Tensions

To offset the increasingly tight supplies of copper concentrate, many Chinese smelters are turning to alternative sources, notably scrap copper, to maintain their production levels. This shift is not merely a minor adjustment but a significant strategic pivot in response to the constraints in concentrate availability.

While the imports of copper concentrate saw a modest increase of just 3.2% in the first 10 months of 2024, the imports of scrap copper surged dramatically by 16% during the same period. This substantial rise in scrap imports highlights the growing reliance on this secondary source of raw material as smelters strive to keep their operations running smoothly.

However, this strategy of leaning heavily on scrap copper is fraught with its own set of complex challenges and uncertainties. One of the most pressing concerns is the potential for U.S.-China trade tensions to severely disrupt the flow of scrap copper imports. Historical precedents underscore this risk; under the previous Trump administration, Chinese imports of scrap copper nearly came to a standstill between 2019 and 2020 due to the imposition of tariffs. These tariffs created significant barriers to trade, leading to a sharp decline in the availability of scrap copper from the U.S., which had been a major supplier.

With Trump expected to adopt a similar hardline stance in the future, Chinese buyers are already taking precautionary measures by reducing their purchases of U.S. scrap copper. This preemptive reduction is significant, considering that U.S. scrap accounted for nearly 20% of China’s total scrap imports in 2024. The potential for renewed trade tensions adds a layer of unpredictability to the already challenging landscape, forcing Chinese smelters to navigate a precarious balance between securing necessary raw materials and managing geopolitical risks.

Survival Strategies for Copper Smelters

Smelters are actively exploring a diverse array of strategies to generate revenue beyond the traditional treatment fees, recognizing the need to adapt in a rapidly changing copper market. One such approach involves leveraging the extraction and sale of valuable by-products that are often found alongside copper in the smelting process. These by-products include precious metals like gold and silver, which can be refined and sold at a premium, providing an additional revenue stream.

Additionally, smelters are capitalizing on the production of sulfuric acid, a by-product of the smelting process, which is in demand for various industrial applications, including fertilizer production and chemical manufacturing. By optimizing the recovery and sale of these by-products, smelters can partially offset the declining treatment charges.

Moreover, smelters are adopting flexible pricing models to better align with market fluctuations and customer needs. This involves negotiating contracts that allow for variable pricing based on market conditions, thereby providing a buffer against volatile copper prices. Such models can include long-term agreements with built-in price adjustments or spot market sales that capitalize on short-term price spikes. Despite these innovative strategies, the relief they offer is limited when weighed against the mounting pressures facing the industry.

The combination of intense competition for mined concentrates, uncertainty in the supply of scrap copper, and the persistent issue of smelter overcapacity presents a formidable challenge for China’s copper industry. As profit margins continue to erode, the prospect of industry consolidation becomes increasingly likely, with smaller and less efficient copper smelters at risk of being absorbed by larger, more resilient entities or forced out of the market altogether. This period of uncertainty underscores the critical need for strategic planning and financial resilience. Copper smelters must not only focus on immediate survival but also on long-term sustainability, investing in technological advancements, operational efficiencies, and strategic partnerships to navigate the turbulent landscape and emerge stronger in the face of adversity.

Trading Copper Futures for Risk Management

As the global copper market grapples with ongoing challenges such as tight concentrate supplies, fluctuating scrap copper availability, and smelter overcapacity, traders have an opportunity to hedge and speculate on future price movements through copper futures. Commodity derivatives can be a valuable tool for managing price risk in this volatile environment.

Orient Futures Singapore offers access to a variety of exchanges where traders can engage in copper futures contracts, including the Shanghai International Energy Exchange (INE), London Metal Exchange (LME), and the Commodity Exchange (COMEX). Utilizing these platforms allows market participants to take positions based on their outlook for copper prices and implement risk management strategies amidst the current market uncertainty.

Start Trading with Orient Futures Singapore

Being an Overseas Intermediary of Shanghai International Energy Exchange (INE), Dalian Commodity Exchange (DCE), and Zhengzhou Commodity Exchange (ZCE), when foreign clients participate in internationalised futures contracts in these Chinese markets with us, they have direct access to trading, clearing, and settlement. Our parent company, Shanghai Orient Futures, is the largest broker in terms of aggregated volume across the five regulated exchanges in China.

Orient Futures Singapore also currently holds memberships at the Singapore Exchange (SGX), Asia Pacific Exchange (APEX), and ICE Futures Singapore (ICE SG). Starting August 2023, corporate clients can also gain access to the B3 Exchange through us, opening additional trading avenues.

Expect streamlined processes and an easy-to-use interface designed for minimal latency, accompanied by our team’s round-the-clock availability on trading days to provide assistance for all your trading needs.